“NEFTMASHTEMIR” As an Open Joint Stock Company (TIN: 9900040501), the company has extensive experience in the field of production and repair of machinery and equipment, pumps and compressors and has been operating since 1960. Our company has always maintained its reputation by working with leading private companies in the country, including state departments and ministries, a participant in large projects. Examples of these are the State Oil Company of the Azerbaijan Republic "AZNEFT" Production Union, "Azerbaijan Demir Yollari" JSC, "BAKU STEEL COMPANY" JSC "Control measuring devices and automation" LLC, "Baku Universal Machine Building" LLC, "Sinam" LLC operating in Azerbaijan. , "Communication and Lighting of Motorways" LLC, "Yanar Dag LTD" LLC, etc. It provides services to reputable companies.

In addition, we would like to inform you that our company operates on the basis of ISO 9001, ISO 14001, ISO 45001 international certificates.

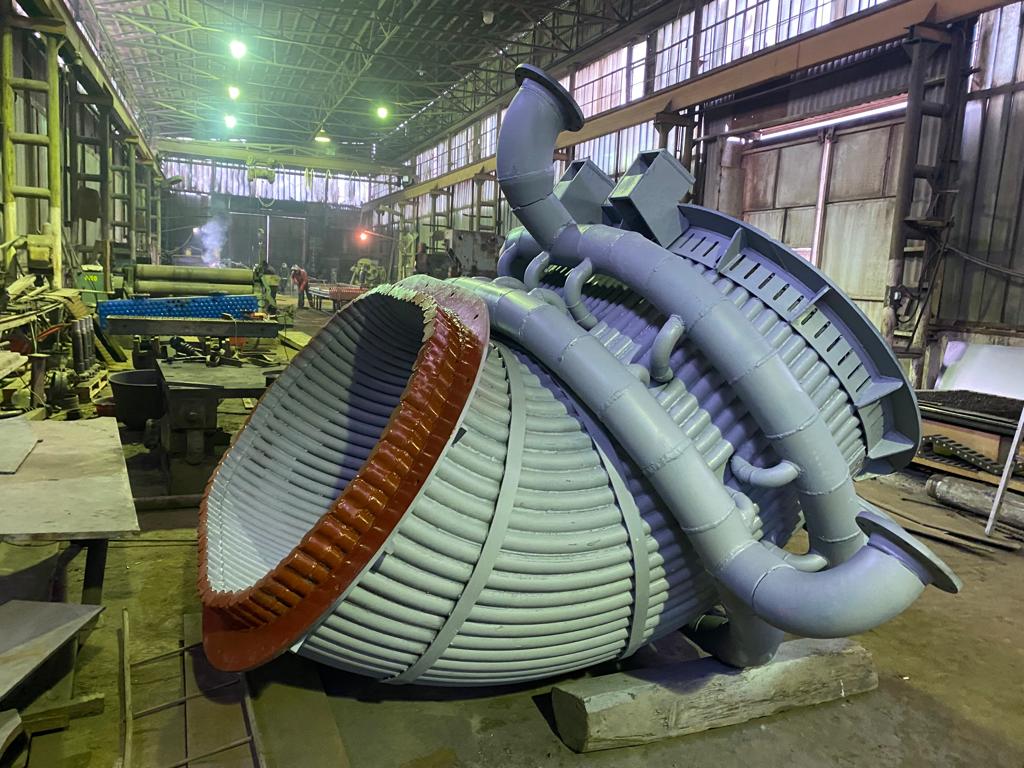

Our company has more than a hundred different types of equipment. Also, in order to ensure quality in our enterprise, many products are processed on lathes controlled by digital software. Our company is available in the areas of metal structure assembly, painting, and sandblasting. At the same time, by ordering new equipment, we further expand our production area, and in our future plans, we include the production of equipment for metal melting furnaces, dust collection devices, production of rolling line equipment, production of agricultural machinery, etc. We plan to expand our activities in the field.

Income Tax Declaration:

Download..

Download..

Download..

Repair of Pumps

REPAİR OF CENTRIFUGAL PUMPS.

The impeller usually consists of two discs - front and rear discs. The working vanes (blades) are located between these two disks. The number of worker feathers is usually 6 to 8. One working wheel can create a pressure of 200...250 m at 3000 revolutions/min. In order to create high pressure, multi-stage (i.e., sequentially placing the impellers on the shaft) pumps are used. In order to increase productivity while maintaining the pressure of one stage of the pump, the impeller is made with two-way liquid inlet. The impeller usually consists of two discs - front and rear discs. The working vanes (blades) are located between these two disks. The number of worker feathers is usually 6 to 8. One working wheel can create a pressure of 200...250 m at 3000 revolutions/min. In order to create high pressure, multi-stage (i.e., sequentially placing the impellers on the shaft) pumps are used. In order to increase productivity while maintaining the pressure of one stage of the pump, the impeller is made with two-way liquid inlet. Spiral chamber – collects the flow of liquid coming out of the impeller at a certain speed. In the conical expander (diffuser), which is a continuation of the spiral chamber, the velocity energy is converted into pressure energy. Pump shaft - transmits the torque of the engine to the impellers, which are stationary on the pump shaft.

Kipchak node - is considered the most responsible node of the pump, it prevents liquid leaks at the outlet of the pump shaft and at the same time does not allow air to enter when there is a vacuum in the pump. Malfunctioning of the pump can damage the pump and cause a fire. Bearings - mainly roller (ball, radial and radial bearing) and sliding bearings are used in pumps. O-rings – placed in the pump body and between the impellers, mainly to prevent fluid leakage between the stages inside the pump body.

Coupling Pipe

THE COUPLER IS THE CONNECTING PART ON WHICH THE BELT ASSEMBLY IS INSTALLED.

Without connecting elements, the pipeline will be a straight segment of a pipe of a certain length. Modern pipeline structures are distinguished by the presence of many parts that have different options for placing them together. They can also have different rotation angles, so these types of parts cannot be omitted during installation. Pipelines made of steel and other metal pipes are installed with the help of various types of couplings. This type of threaded joints is used when pipeline elements cannot rotate around their axes.

Our factory takes into account all the details and records down to the smallest details of the compounds it produces. For this reason, the material is selected according to the type of pipelines. The connectors we manufacture are installed using additional materials that increase the quality of the connections.

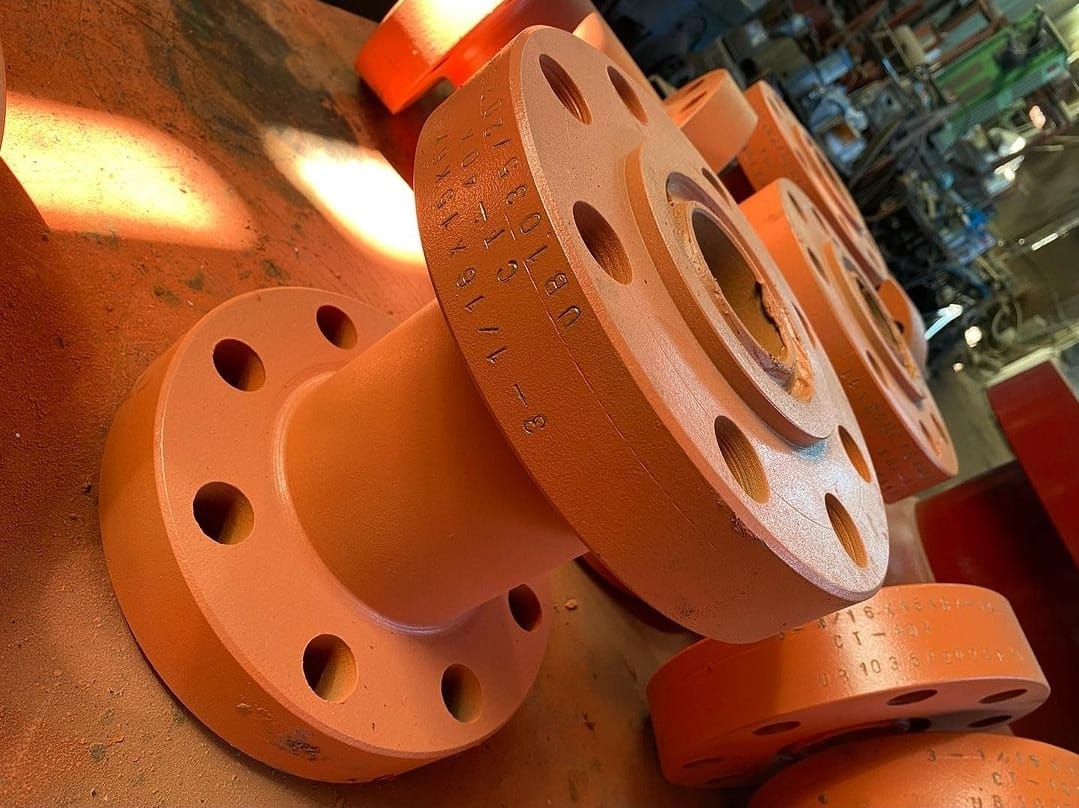

In addition, you can easily connect plastic and metal products using our connectors. Currently, there are several types of these connecting elements, each of which has its own characteristics. We also provide universal options that can be used in almost any situation. In addition, our plant has extensive experience in the production of flanges for oil companies. The flange is the part connecting the shaft to the shaft used for connection between pipe ends; it is also used for connection between two pieces of equipment, such as a reducer flange at the inlet and outlet of the equipment. Flange connection or flange joint refers to a separable joint with flange, gasket and bolt as a group of joint sealing structure. Piping flange refers to the flange used for piping in a piping device, and for equipment, it refers to the inlet and outlet flange of the equipment. There are holes in the flange and bolts tightly connect the two flanges. The flange is sealed with a gasket. The flange is divided into threaded joint (threaded joint) flange, welding flange and clamp flange. The flange is used in pairs, the low-pressure pipeline can use the screw flange, and the pressure of more than four kilograms can use the welding flange. Add a gasket between the two flange plates and then fasten them with bolts. The flange thickness of different pressure is different and they use different bolts.

Industrial Reducers

SPARE PART OF INDUSTRIAL REDUCERS

These spare parts can be used in gearboxes of all major manufacturers. The delivery time will be as short as possible due to the comprehensive performance of all work operations by the "Neftmashtamir" plant for the production of the spare part. The service network of our factory provides high-quality and timely service.

Production and sale of all types of spare parts is possible regardless of the manufacturer. The spare parts will be produced in short time keeping strict quality standards according to the sketches, drawings and samples provided by the customer. The supplied components and spare parts have a long life, resistance to high mechanical and dynamic loads. Thanks to the increased power, the products remain operational for a long time.

Such a purchase will definitely meet the customer's expectations, increase the efficiency and productivity of not only the serviced units, but also the production processes in general. Our factory, which widely uses modern technologies in its work, offers you a wide range of any spare parts.

Shaft Rotation

SHAFT — AS A COMPONENT PART OF EQUIPMENT WITH A ROTATING SURFACE, IT IS APPLIED TO SUPPORT ROTATING PARTS.

We offer a warranty for all our products, from one star to complex non-standard equipment. This will ensure that you are sure of your choice and quality. In small and medium-scale production, the outer surfaces of the shafts are made on universal machines. Despite the variety of size and design, the shafts are processed according to a single technological scheme.

Depending on the dimensions of the shafts, the technological process of their production may differ only by the processing sequence or the application of additional operations. The dimensions of the shafts are generally complex. Some shafts have radial holes (for oil supply).

The most commonly used are stepped shafts. There are grooves or transition surfaces when moving from one stage to another. Some shafts need dynamic balancing. We closely monitor all developments in the sector and work in cooperation with both our clients and other sector stakeholders.

Mechanical Valves

MECHANICAL VALVES ARE IN VARIOUS SIZES ACCORDING TO INTERNATIONAL STANDARDS.

Mechanical valves are generally used to control engine or cylinder direction; they can also perform other functions in one cycle. Valves are used mechanically or electronically. Mechanical valves also perform different functions, ensuring better system operation.

Our plant has been providing stability and reliability, as well as diversity, of mechanical valves since its inception. It provides a solution partnership to companies, providing you with the most suitable option among hundreds of brands and thousands of product options.

-Valves are devices designed to close, open and regulate the flow of liquid (gas) to the technological line under certain conditions (pressure, temperature, increase in consumption, the need to change the flow direction, etc.). The main role of valves as an executive mechanism in automatic control systems is to adjust the flow of liquid in the pipe in which it is installed based on the signal received from the controller, redirect it to another line or completely open and close it. Valves mainly consist of two parts. 1. The main part (body) consists of mechanical parts that can come into contact with the liquid (gas, etc.) flowing in the pipeline and directly affect it. 2. Actuators. This part of the valve consists of a mechanism that can move the moving mechanical part (stock) of the valve using different types of energy (electrical, pneumatic, hydraulic).

Sprockets

GEAR WHEELS ARE MECHANISMS WHICH HAVE THE WIDEST RANGE OF USE, WHICH CAN BE USED, TRANSMISSIONABLE, AND HOLD A SPECIAL POSITION IN BOTH POWER AND SPEED.

"Neftmashtamir" is the main solution partner of the sector in the production of strong and high-quality gears. Since many years, it has done significant work aiming at honesty and customer satisfaction. We update ourselves due to technological developments and work tirelessly with a team spirit in which all our employees actively participate to increase customer satisfaction and meet the current and future expectations of our customers.

Liquid and gas cementation is carried out using steel material in the production of gears. Referral and profile checks are performed continuously. Gears used in construction machinery and gearboxes are an important tool in terms of position. We have gears of any size you want and can also manufacture them according to world standards if required. The gears we manufacture are manufactured with ASA and RH factors.

Single-row, double-row, three-row and four-row chain gears and special types of chain gears are produced. We offer gears to our valued customers at optimum prices without compromising on quality, precision and customer satisfaction.

Gallery

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View more

NeftMashTemir

View moreServices

Oilfield equipment

Patterned light poles

Benches with cast iron arms

Railings, aluminum casting patterns, water drains, well covers, water grates, etc. Cardan, shaft, cylinder, zadvishka, some metal spare parts of tractors, rollers of tractors with seeds, teeth of mines, etc.

Mechanical spare parts of agricultural machinery.

Many spare parts of railway locomotives

Large shafts, cardan shafts, mechanical joints, etc., used in brick factories, mills, stone quarries, etc.

Preparation of different types of gears (straight, curved, spiral, chevron).

A large gear set of the wheel top of the VL-11 type electric locomotive

ER-2 small gear

ER-2 draft reducer support

Reductor

Gear set

Auto troop hanger set

Compressor clutch

Kristavin (for engine)

Small cover of the TL-2K Dart engine

Labyrinth

Wheel Z23 gear wheel of VL-11 type electric locomotive

Z21 gear of the VL-8 electric locomotive

VL-11 type electric locomotive hanger complete set

VL-11 type electric locomotive hinge

Repair of the wheel center of the VL-8 type electric locomotive

The body of the cochlear to cast the axle bearing of the engine

Electric locomotive trailer central beam

Induction heater front cover

The inner part of the cochlear for casting of the engine's axle bearing

Butterfly Valve

Y-type, Disc-type, Ball Check Valves

Dismantling parts

Metal compounds

Elbows

Metal case

Ball valve

Metal straight transition

Compensator

Metal elbows

Metal araqat

Triple pass

Flanged valve, thin flange, metal blind flange

Carve U-PVC

U-PVC plug

HDPE Coupling Valves

Araqats

Sliding Drawer

Butterfly Valve

Threaded and non-threaded joints

Production of spare parts of various types of compressors and pumps

Fountain fittings

Gear wheels

Casting works

Contact

Location:

Zabrat 1 Qəs., 18 Oktyabr Küç., 52Azərbaycan, Bakı,

Email:

info@neftmashtemir.az

Our Phones:

+994(12) 550 27 86

+994(70) 402 17 47